Smilar to conventional (inorganic)

semiconductors, organic semiconductors can be used for

devices such as organic photovoltaics (OPV).

While the charge carrier mobility and the photovoltaic

efficiency is not assumed to rival that of, silicon-based

photovoltaics, the idea for OPV is to produce OPV cells at

lower cost and in particular lower energy consumption than for

silicon.

Another important issue is that organic devices may be made

mechanically flexible and thinner than silicon (thanks to

their higher optical absorption, i.e. stronger transitions),

which potentially opens up completely new applications not

possible with silicon technology, such as OPV on clothes, e.g.

In order to optimise and use these systems in applications,

research is required to understand the fundamental mechanisms

underlying OPV. This is the subject of a focus program funded

by the DFG, in which are participating.

Smilar to conventional (inorganic)

semiconductors, organic semiconductors can be used for

devices such as organic photovoltaics (OPV).

While the charge carrier mobility and the photovoltaic

efficiency is not assumed to rival that of, silicon-based

photovoltaics, the idea for OPV is to produce OPV cells at

lower cost and in particular lower energy consumption than for

silicon.

Another important issue is that organic devices may be made

mechanically flexible and thinner than silicon (thanks to

their higher optical absorption, i.e. stronger transitions),

which potentially opens up completely new applications not

possible with silicon technology, such as OPV on clothes, e.g.

In order to optimise and use these systems in applications,

research is required to understand the fundamental mechanisms

underlying OPV. This is the subject of a focus program funded

by the DFG, in which are participating.

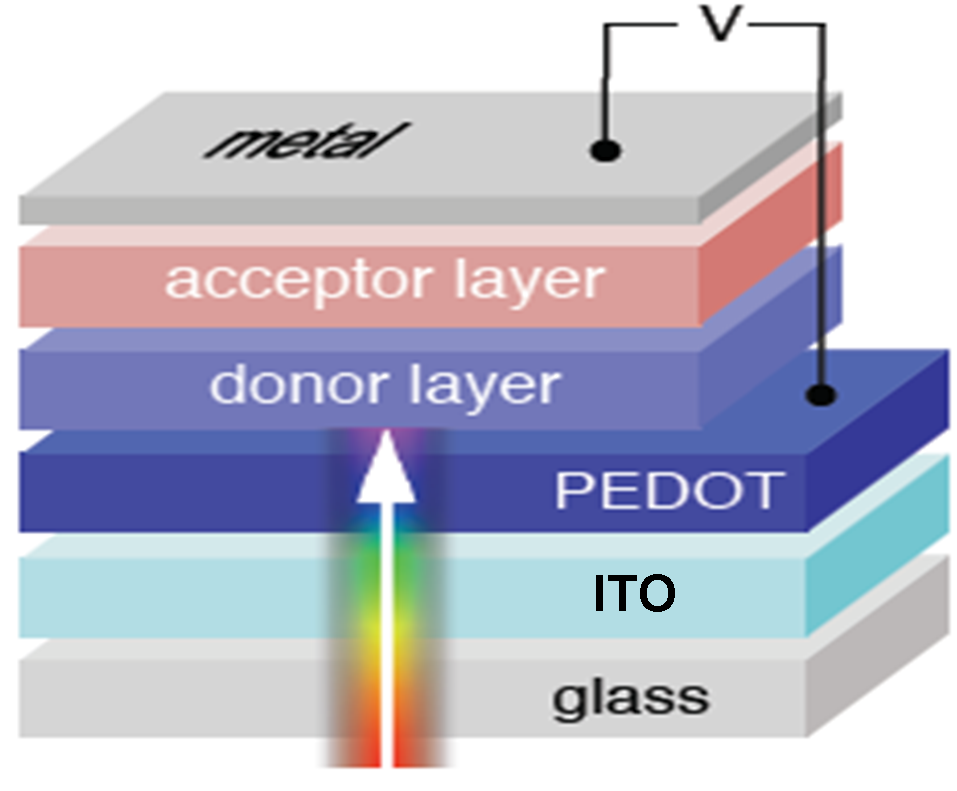

Organic solar cells basically consist of an organic

semiconductor in contact with two metal electrodes, which

collect the charge carriers produced in the semiconductor upon

light irradiation. In order to illuminate the semiconductor

material at least one of the two electrodes has to be

transparent. Glass or plastic substrates coated with ITO

(indium tin oxide, a conductive oxide with low resistivity,

high transparency in the visible and a relatively high work

function [1]) are commonly used for this purpose.

On top of the ITO a buffer layer may be deposited. The most

common material used is the polymer blend PEDOT:PSS, an

organic conducting material with relatively good

electrochemical, ambient and thermal stability. Moreover, the

electrical properties of PEDOT:PSS can be varied by changing

the mixing ratio of the blend [2]. The reported benefits of

PEDOT:PSS films between the ITO and the photovoltaic active

layer are:

- preventing indium diffusion in the semiconductors

- improving the compatibility between the energy levels of the organic semiconductors with the work function of the electrode [3].

In order to collect the photo-generated charges

the second metallic contact (e.g. Al, Ag) is deposited on top

of the active material.

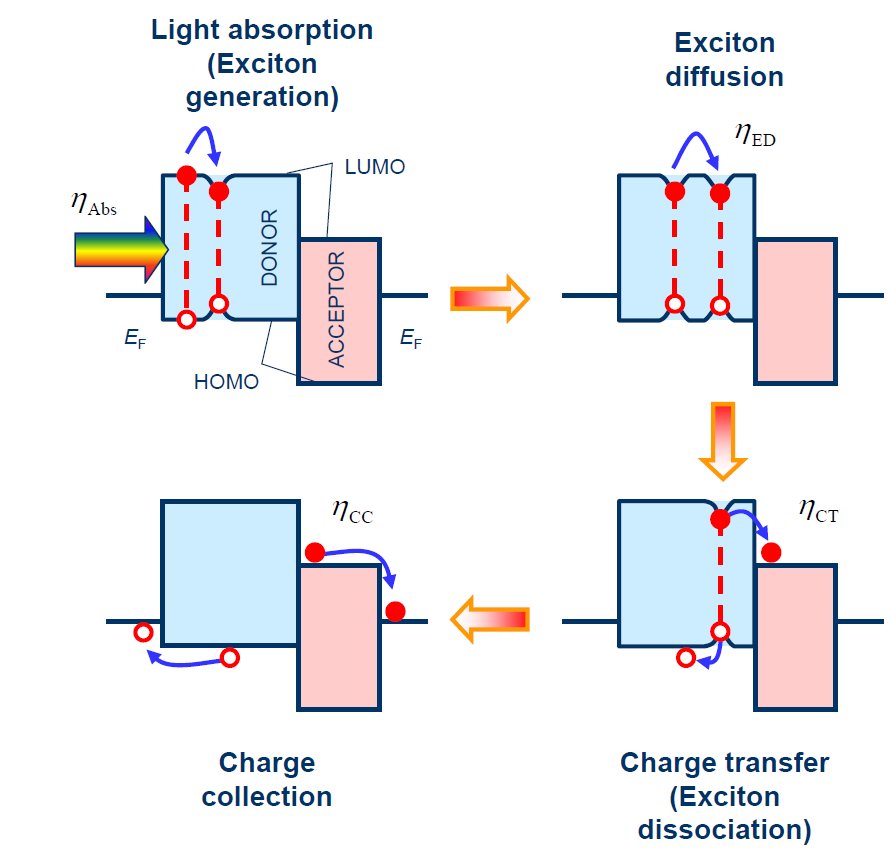

The photo-active layer usually consists of a hetero-junction

formed by two different semiconductors, i.e. an electron-donor

(D) and an electron-acceptor (A) material. Donor molecules

exhibit a low ionization potential (high HOMO energy), while

acceptor molecules have a high electron affinity (low LUMO

energy). Visible light may excite electrons from the HOMO to

the LUMO level, therefore leaving a hole in the HOMO

level. The relatively low dielectric constant in organic

materials leads to the formation of a neutral bound

electron-hole pair, known as exciton.

The organic semiconductors have to be chosen properly for the

hetero-junction, so that the electronic band structure of the

donor and acceptor materials is matched. The different

alignment of the HOMO and LUMO levels allows for exciton

dissociation at the interface. Electrons are then transferred

through the acceptor and collected by the electrode (Al),

while the respective holes diffuse in the acceptor and then in

the ITO electrode.

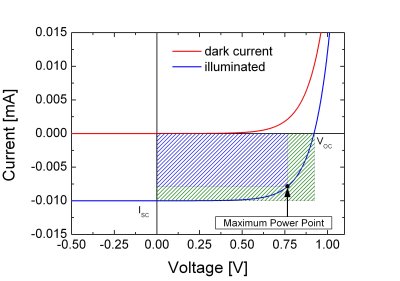

To determine the electric behaviour of a solar cell the

current-vs-voltage characteristic is measured. One may

distinguish different regimes:

In order to collect the photo-generated charges

the second metallic contact (e.g. Al, Ag) is deposited on top

of the active material.

The photo-active layer usually consists of a hetero-junction

formed by two different semiconductors, i.e. an electron-donor

(D) and an electron-acceptor (A) material. Donor molecules

exhibit a low ionization potential (high HOMO energy), while

acceptor molecules have a high electron affinity (low LUMO

energy). Visible light may excite electrons from the HOMO to

the LUMO level, therefore leaving a hole in the HOMO

level. The relatively low dielectric constant in organic

materials leads to the formation of a neutral bound

electron-hole pair, known as exciton.

The organic semiconductors have to be chosen properly for the

hetero-junction, so that the electronic band structure of the

donor and acceptor materials is matched. The different

alignment of the HOMO and LUMO levels allows for exciton

dissociation at the interface. Electrons are then transferred

through the acceptor and collected by the electrode (Al),

while the respective holes diffuse in the acceptor and then in

the ITO electrode.

To determine the electric behaviour of a solar cell the

current-vs-voltage characteristic is measured. One may

distinguish different regimes:

- If no external voltage is applied, no current flows through the junction.

- If an external voltage is applied under reverse bias, a current flux is possible.

- If an external voltage is applied in forward bias condition, current flow is allowed.

Upon illumination, the device will act as a current generator, therefore the I-V curve shifts downward, as illustrated in the figure below.

In order to produce such devices on a

conducting transparent substrate, the photo-active materials

have to be deposited. Two main types of techniques are

available:

In order to produce such devices on a

conducting transparent substrate, the photo-active materials

have to be deposited. Two main types of techniques are

available: